Expert Commercial Walk-in Cooler Repair and Installation Services in the UK

Is your business experiencing inconsistent temperatures, refrigerant leaks, or sudden breakdowns in your walk-in cooler? With perishable stock at risk and downtime costing hundreds per hour, dependable walk-in cooler repair and installation is crucial. This guide will cover the most common cooler faults, explain our rapid diagnosis and repair process, outline professional installation essentials, and demonstrate how planned maintenance and emergency support keep your refrigeration running smoothly. You’ll discover:

- Common issues and targeted solutions for compressors, coils, and seals

- Step-by-step repair procedures, from leak detection to calibration

- Installation planning, energy-efficient design options, and cooler types

- Why AccuTemp’s certified engineers, 24/7 call-out, and minimal disruption approach provide peace of mind

- How preventative maintenance and industry-specific services protect your bottom line

What Are the Most Common Walk-in Cooler Problems We Repair?

Walk-in cooler performance relies on precise temperature control, so faults in key components lead to rapid spoilage and wasted energy. Understanding these issues and their solutions safeguards your perishable inventory and reduces energy bills.

How Do Temperature Fluctuations Affect Walk-in Cooler Performance?

Temperature fluctuations occur when cooling cycles fail to regulate internal conditions reliably. A faulty thermostat or a blocked condenser forces the compressor to run continuously or cycle on and off too frequently, resulting in:

- Product Spoilage – Frequent temperature swings degrade food quality.

- Energy Inefficiency – Constant cycling drives up electricity consumption.

- Component Stress – Overworked compressors wear out prematurely.

By replacing faulty thermostats, cleaning condenser coils, and recalibrating control units, AccuTemp restores stable cooling cycles and extends equipment lifespan.

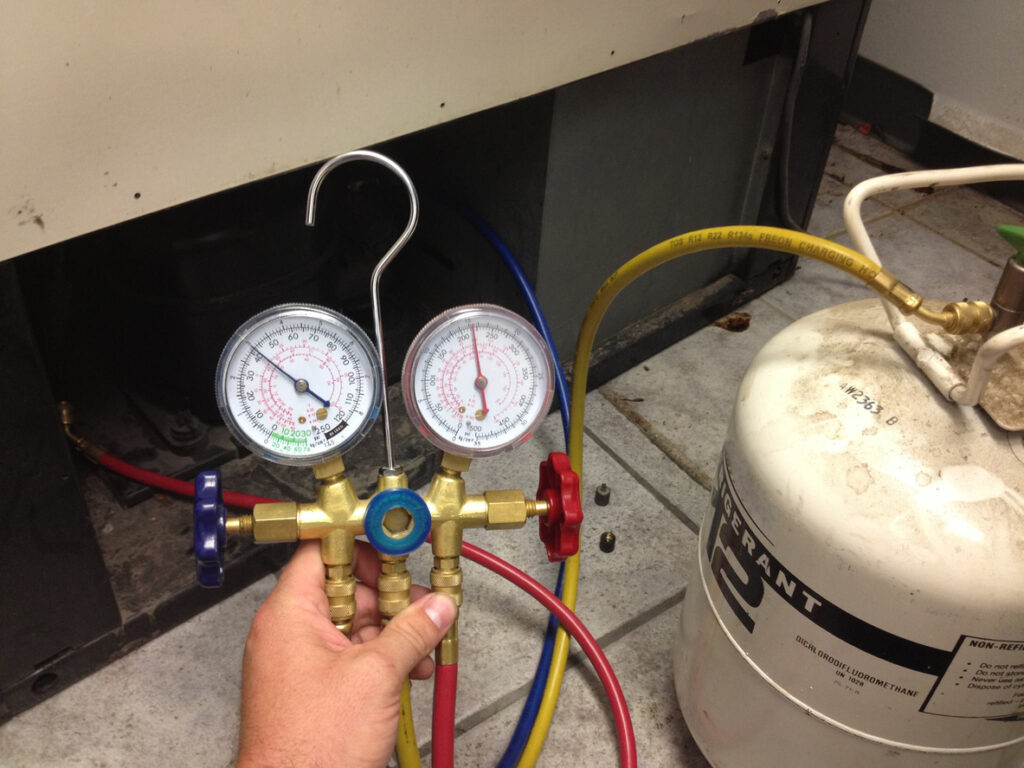

What Are the Signs and Solutions for Refrigerant Leaks?

Refrigerant leaks reduce cooling capacity and harm the environment. Common indicators include hissing sounds, ice formation on lines, and rising internal temperatures. Effective leak repair involves:

- Electronic leak detection to pinpoint even tiny fissures

- Sealing or replacing damaged tubing and fittings

- Recharging with approved, eco-friendly refrigerant blends

Proper sealing and pressure testing ensure your system maintains optimal pressure and prevents recurring leaks.

How Do Compressor and Condenser Failures Impact Cooling?

A worn compressor or a blocked condenser hinders heat extraction, leading to inadequate chilling. Symptoms include:

- Loud grinding or rattling noises from the compressor housing

- The system running without ever reaching the set temperature

- Warm air exiting the condenser unit

We perform comprehensive diagnostic testing, rebuild or replace compressors, and thoroughly clean or replace condenser units. Restoring heat-exchange efficiency immediately brings your walk-in cooler back to peak performance.

Why Is Evaporator Coil Icing a Problem and How Is It Fixed?

Evaporator coil icing obstructs refrigerant flow and heat absorption. Ice forms when:

- Drain pan blockages prevent proper defrost drainage

- Faulty defrost timers or heaters fail to melt frost

- A low refrigerant charge causes freezing

Our service includes inspecting the defrost cycle, clearing drain lines, and replacing faulty thermostatic expansion valves. Clearing ice ensures continuous heat absorption and consistent cooling.

How Do Faulty Door Seals and Closers Affect Energy Efficiency?

Damaged gaskets and misaligned door closers allow warm air to enter, forcing the refrigeration system to work harder. This leads to:

- Increased running time and higher energy costs

- Uneven temperature zones and frost on internal walls

- Accelerated wear on compressors

Replacing seals and adjusting door closers restores airtight integrity, significantly cuts energy consumption, and maintains uniform internal temperatures.

How Does the Walk-in Cooler Repair Process Work?

At AccuTemp, we follow a structured repair workflow to minimise downtime and deliver lasting solutions.

What Steps Are Involved in Rapid Diagnosis and Fault Finding?

Our engineers start with a thorough inspection, checking:

- Temperature logs and pressure readings

- The visual condition of coils, fans, and electrical connections

- Refrigerant charge level and for any leaks

This systematic approach quickly identifies the root causes and informs the most effective repair strategy.

How Are Compressor and Other Component Repairs Performed?

Once faults are identified, we proceed with component servicing:

- Compressor overhaul or replacement using manufacturer-approved units

- Condenser coil cleaning or replacement to restore heat-expulsion efficiency

- Evaporator coil refurbishment, including acid cleaning if necessary

Every repair uses genuine parts and adheres to industry best practices to meet safety standards and maintain warranty coverage.

What Is Refrigerant Recharging and Leak Repair?

After sealing any leaks, we evacuate residual contaminants and recharge the system:

- A deep vacuum pump cycle to remove moisture and air

- Precise refrigerant metering based on manufacturer specifications

- System pressurisation and a retest for leaks

This ensures optimal refrigerant flow, correct pressure balance, and compliance with F-Gas regulations.

How Is Post-Repair Testing and Calibration Conducted?

Final checks confirm a full restoration of performance:

- Accuracy testing of thermostat setpoints

- Observation of operational cycles across multiple defrost and cooling phases

- Energy consumption analysis to verify efficiency improvements

Calibrated controls and validated performance deliver reliable cooling and lower operating costs.

What Should You Know About Professional Walk-in Cooler Installation?

Proper installation is the foundation for long-term performance and energy savings. Careful planning and expert execution prevent future breakdowns.

An Examination of Walk-in Coolers: Definition, Classifications, and Utilisation

Walk-in coolers are refrigerated, insulated compartments of room size, designed for the storage of foodstuffs. These units typically encompass areas of 280 m² (3,000 ft²) or less. They are classified either as coolers, operating above 0°C (32°F) (medium-temperature) for the storage of fresh produce and dairy products, or as freezers, operating below 0°C (32°F) (low-temperature) to comply with health and safety regulations for frozen food products. Walk-in units are commonly installed in catering establishments, as well as in small, medium, and large retail food outlets such as grocery stores and supermarkets.

A Novel Approach to Visualize and Quantify the Transient Air Infiltration/Exfiltration in Walk-in Coolers, R Faramarzi, 2018

What Types of Walk-in Coolers Are Available for Installation?

| Cooler Type | Description | Ideal Use Case |

|---|---|---|

| Modular Panel System | Pre-manufactured insulated panels assembled on-site | Fast turnaround, budget installations |

| Bespoke Custom Build | Tailored framing and insulation for unique spaces | Irregular footprints, premium fit-outs |

| Prefabricated Box | Fully assembled units delivered and set in place | Quick install, limited site prep |

How Is Walk-in Cooler Design and Planning Conducted?

Design begins with load calculations, taking into account:

- Daily door openings and product turnover rates

- Ambient temperature and humidity levels

- Racking configuration and airflow requirements

Our engineers produce detailed CAD layouts, specifying panel thickness, refrigeration capacity, and electrical load, ensuring seamless integration with your existing infrastructure.

What Are the Benefits of Energy-Efficient Walk-in Cooler Solutions?

Energy-efficient systems reduce utility bills and your carbon footprint by:

- Utilising low-GWP refrigerants for enhanced thermodynamic performance

- Installing high-efficiency compressors with variable-speed drives

- Incorporating advanced insulation materials and LED lighting

These measures typically achieve 20–30 percent energy savings and help you meet your sustainability objectives.

Why Choose AccuTemp for Your Walk-in Cooler Repair and Installation?

AccuTemp combines technical expertise, rapid response, and a customer-centric approach to safeguard your perishable assets.

What Certifications and Experience Do Our Refrigeration Engineers Have?

All our technicians are F-Gas certified and hold recognised HVAC qualifications. Years of commercial refrigeration experience underpin their ability to handle complex breakdowns and bespoke installations with precision and compliance.

How Does Our 24/7 Emergency Service Minimise Business Downtime?

Unexpected cooler failures can bring operations to a standstill. Our round-the-clock call-out service ensures an engineer arrives within hours, not days, to diagnose issues and implement temporary or permanent fixes that keep your business running.

How Do We Ensure Minimal Disruption During Repairs and Installations?

We work around your schedule, utilising night-time or weekend shifts whenever possible. Every project follows a detailed service plan with clear timelines, minimising impact on your staff and customers, and maintaining a clean, safe work environment.

How Can Planned Preventative Maintenance Extend Your Walk-in Cooler’s Lifespan?

Regular maintenance prevents sudden failures and sustains peak performance for years to come.

What Are the Key Benefits of Commercial Refrigeration Maintenance Plans?

A structured maintenance contract provides:

- Fewer emergency call-outs and unplanned repairs

- Consistent energy efficiency and lower utility bills

- Early detection of wear on critical components

- Streamlined budgeting with fixed service fees

Preventative care typically extends equipment life by up to 50 percent, maximising your return on investment.

How Does F-Gas Compliance Affect Maintenance and Refrigerant Management?

UK regulations mandate accurate refrigerant records, leak checks, and certified handling. Our maintenance service includes:

- Scheduled refrigerant pressure inspections

- Leak detection reports and repair documentation

- Certified disposal and recharging of regulated gases

This ensures legal compliance and environmental responsibility.

Commercial Walk-in Refrigeration Systems: Design and Lifecycle Compliance

The design of refrigeration systems must strictly comply with the regulations determined by the lifecycle assessment of two commercial refrigeration systems incorporating walk-in cold rooms (for medium- and low-temperature applications).

Comparative Carbon Footprint Assessment of commercial walk-in refrigeration systems under different use configurations, M Gamberi, 2016

How Often Should Walk-in Coolers Be Serviced for Optimal Performance?

We recommend at least bi-annual inspections for standard usage, with quarterly visits for high-traffic operations such as restaurants and food processing facilities. Frequent checks catch issues before they escalate into costly downtime.

What Emergency Walk-in Cooler Repair Services Are Available?

When time is of the essence, our emergency protocols deliver fast, effective support.

How Does Our 24/7 Emergency Call-Out Service Operate?

Our emergency hotline is monitored around the clock. Once alerted, a certified engineer is dispatched immediately with diagnostic tools and common spare parts, enabling on-site fault identification within the first hour.

What Steps Do We Take to Minimise Downtime During Emergency Repairs?

We carry critical components in our service vehicles, implement temporary bypass solutions if necessary, and expedite any required parts through our preferred supplier network. This combined approach restores partial or full cooling capacity within hours, not days.

How Do We Support Specific Industries with Walk-in Cooler and Restaurant Refrigeration Repair?

AccuTemp’s sector expertise ensures tailored solutions for a diverse range of commercial clients.

What Are Common Refrigeration Issues in Restaurants and Foodservice?

High-usage environments frequently encounter:

- Rapid defrost cycle failures

- Heat gain from frequent door openings

- Condensers clogged with grease and debris

Our targeted cleaning schedules, door usage sensors, and robust sealing solutions keep kitchens operational and energy costs down.

How Do We Repair Reach-in Coolers and Beer Cave Coolers?

Reach-in units and specialised beer cellars require precise temperature and humidity control. We service compressors, thermostats, and humidity regulators, and install line-set insulation upgrades to prevent ice build-up and product spoilage.

What Solutions Do We Offer for Cold Room Repair in London and Surrounding Areas?

For large-scale cold rooms, we provide:

| Service | Feature | Benefit |

|---|---|---|

| Insulation Panel Repair | Rapid panel replacement | Restores thermal integrity and reduces load |

| Multi-Door Seal Overhaul | High-density gasket installation | Eliminates warm air ingress and cuts energy loss |

| Redundant Compressor Line | Backup compressor integration | Ensures continuous operation during malfunctions |

These specialised interventions guarantee uninterrupted cold storage and regulatory compliance across London, Essex, and the wider South East.

With skilled engineers, rigorous processes, and 24/7 availability, AccuTemp delivers dependable walk-in cooler repair, installation, and maintenance that save energy, reduce downtime, and protect your investment. Contact us today to arrange expert refrigeration support and keep your business cool under pressure.